Identity documents play a crucial role in modern – day society. They are used for various purposes such as age verification, accessing services, and legal identification. However, the existence of fake ID cards has become a significant concern, and UV technology has emerged as an important tool in both detecting and, unfortunately, in some malicious cases, creating these counterfeits.

UV Technology Basics

UV (ultraviolet) light is a type of electromagnetic radiation with a wavelength shorter than that of visible light but longer than X – rays. There are three main types of UV light: UVA, UVB, and UVC. In the context of ID card analysis, UVA and UVB are more commonly used. Many materials, when exposed to UV light, exhibit fluorescence or phosphorescence. Fluorescence is the immediate emission of light by a substance after it has absorbed UV energy, while phosphorescence is a delayed emission.

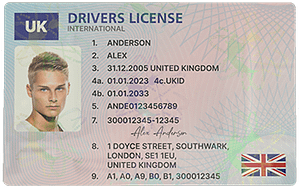

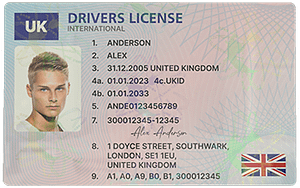

UV – reactive inks and materials are often incorporated into the design of legitimate ID cards. These inks can be used to print various security features such as logos, text, or patterns that are invisible under normal light but become highly visible when exposed to UV light. This makes it difficult for counterfeiters to replicate the ID card accurately.

Detecting Fake ID Cards with UV Technology

When it comes to detecting fake ID cards, UV technology offers several key advantages. Security personnel, such as bouncers in nightclubs, border control officers, and bank tellers, often use UV lamps to inspect ID cards. The first step is to check for the presence of UV – reactive features that are supposed to be on the legitimate card.

For example, many government – issued ID cards have UV – fluorescent watermarks. These watermarks are usually in the form of the national emblem, a portrait, or other identifying symbols. When the card is illuminated with a UV lamp, the watermark should appear clearly and in the correct position. If the watermark is missing, distorted, or in the wrong place, it could be a sign of a fake ID card.

Another aspect is the examination of UV – reactive inks used for text and graphics. Legitimate ID cards may have text printed with UV – sensitive inks that glow in a specific color under UV light. Counterfeiters may not be able to reproduce these inks accurately, leading to differences in color, intensity, or even the absence of fluorescence. By comparing the UV – induced glow of the ID card with known samples of legitimate cards, it becomes possible to identify forgeries.

UV technology can also be used in combination with other security – checking methods. For instance, along with visual inspection and magnetic – stripe or chip – based verification, UV inspection provides an additional layer of security. This multi – faceted approach increases the chances of detecting fake ID cards effectively.

Malicious Use of UV Technology in Creating Fake ID Cards

Unfortunately, some individuals with malicious intent have also exploited UV technology to create fake ID cards. Counterfeiters may try to replicate the UV – reactive features of legitimate cards. They may source UV – reactive inks and materials and use them to print fake ID cards. However, their attempts are often less than perfect.

One common issue for counterfeiters is that they may not be able to obtain the exact same UV – reactive inks as those used in the production of legitimate ID cards. These inks are often proprietary and closely guarded by the manufacturers. As a result, the color, intensity, and other characteristics of the UV – induced glow on the fake cards may differ from the real ones. For example, the UV – fluorescent watermark on a fake card may have a slightly different hue or may not be as well – defined as on a legitimate card.

Another challenge for counterfeiters is the precise placement of UV – reactive features. Legitimate ID cards have these features in specific locations and with a high degree of accuracy. Counterfeiters may struggle to replicate this precision, and any misplacement can be a tell – tale sign of a fake card. Additionally, the overall quality of the UV – reactive printing on fake cards is often inferior to that on legitimate cards, with issues such as uneven application of the ink or smudging.

Common Problems and Solutions in UV – based ID Card Detection

- Problem: Inconsistent UV Lamp Quality

Some low – quality UV lamps may not emit the correct wavelength of UV light or may have an uneven distribution of light. This can lead to inaccurate detection of UV – reactive features on ID cards.

Solution: Use high – quality UV lamps that are specifically designed for ID card inspection. These lamps should have a consistent wavelength output and a uniform light distribution. Regularly calibrate the lamps to ensure they are functioning correctly.

- Problem: Ambient Light Interference

In environments with high levels of ambient light, especially if it contains some UV components, it can be difficult to clearly see the UV – induced glow on ID cards. This can result in false negatives or missed detections.

Solution: Use UV – inspection booths or enclosures that block out ambient light. Alternatively, perform UV inspections in a dimly – lit area or at night to minimize the impact of ambient light.

- Problem: Lack of Training for Inspectors

Inspectors may not be fully trained in recognizing the correct UV – reactive features on different types of ID cards. They may also not be aware of the common variations and characteristics of fake cards under UV light.

Solution: Provide comprehensive training programs for ID card inspectors. These programs should cover the different types of UV – reactive features on legitimate cards, as well as the typical signs of fake cards under UV inspection. Regularly update the training to keep up with the latest ID card security features and counterfeiting techniques.

- Problem: Counterfeiters Adapting to Detection Methods

As counterfeiters become more aware of UV – based detection methods, they may try to develop new ways to replicate UV – reactive features more accurately. This can make it harder to detect fake ID cards using traditional UV – inspection techniques.

Solution: Continuously innovate and improve ID card security features. Incorporate more complex and unique UV – reactive elements that are difficult for counterfeiters to replicate. Also, develop new UV – inspection technologies and algorithms that can better distinguish between real and fake UV – reactive features.

- Problem: False Positives

Some materials or substances on an ID card, other than the intended UV – reactive security features, may also fluoresce under UV light. This can lead to false positives, where a legitimate card is wrongly identified as a fake.

Solution: Establish a comprehensive reference database of the normal fluorescence characteristics of various materials and substances that may be present on legitimate ID cards. Train inspectors to be able to distinguish between normal fluorescence and the specific UV – reactive security features of the ID card.

UV technology is a powerful tool in the fight against fake ID cards. While it has been misused by some counterfeiters, its proper application in detection can significantly enhance the security of identity documents. By addressing the common problems associated with UV – based ID card detection and continuously improving security measures, we can better safeguard the integrity of identity verification systems.