Introduction

Fake ID cards have long been a concern in society, and understanding the materials used in their creation can help in detection and prevention efforts. These illegal documents are often used for various improper purposes such as under – age drinking, false identification for illegal activities, or bypassing age – restricted services. By delving into the common materials, we can gain insights into how these counterfeit items are made.

Plastic – A Predominant Material

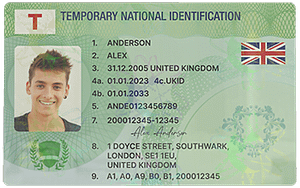

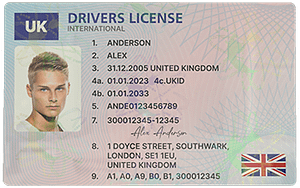

Plastic is one of the most commonly used materials in making fake ID cards. This is because many legitimate ID cards, such as driver’s licenses and identification cards issued by government agencies, are also made of plastic. Counterfeiters aim to mimic the look and feel of real ID cards, and plastic provides a similar texture and durability.

There are different types of plastics used. Polyvinyl chloride (PVC) is a popular choice. It can be printed on easily using specialized printers. Counterfeiters may use inkjet or laser printers to print details such as the cardholder’s photo, name, date of birth, and other identifying information onto the PVC. After printing, a layer of laminate is often added. This laminate serves multiple purposes. It protects the printed information from wear and tear, gives the card a more professional look, and can also be used to add holographic or security – like features that are present on real ID cards. However, the quality of these added features in fake cards is usually far from the sophisticated security features on genuine ones.

Paper – An Alternative but Less Durable Option

Paper is another material that can be used to make fake ID cards, although it is less common and less durable compared to plastic. In some cases, especially for very basic or low – quality fake ID attempts, paper may be used. Counterfeiters will print all the necessary information on a sheet of paper. This could be regular printer paper or a thicker, more card – like paper stock for a more convincing look.

To make the paper ID seem more legitimate, they may try to add elements such as a photo glued on, or use stamps or stickers to add details like a signature or a government seal. However, paper IDs are easily detectable as they lack the durability and security features of plastic – based ID cards. They can be easily torn, and the glued – on or stamped elements may look out of place or not adhere properly over time.

Cardboard – For Low – Tech Fakes

Cardboard is a very basic material used in some extremely low – tech fake ID card attempts. It is often used by those who are not very skilled in counterfeiting or are doing it on a very limited budget. Counterfeiters will cut a piece of cardboard to the size of a standard ID card and then print or write the necessary information on it.

They may try to add a photo by gluing it on, but the overall appearance is usually very crude. Cardboard fake IDs are not suitable for serious attempts at deception as they are very easy to spot due to their thickness, lack of proper lamination, and the fact that they are made from a non – standard ID material. They are more likely to be used in pranks or very informal situations where a high – quality fake is not required.

Security Threads and Holograms (Fake Versions)

To make fake ID cards seem more real, counterfeiters may attempt to replicate security features such as security threads and holograms. For security threads, they may use thin strips of metallic or colored plastic. These strips are usually glued or inserted between layers of the card material (such as plastic layers in a PVC – based fake ID). However, the quality and placement of these fake security threads are often not as precise as in real ID cards.

Holograms are also a target for replication. Counterfeiters may use stickers or printed images that resemble holograms. These are usually added to the surface of the fake ID card. But real holograms are complex optical elements that are difficult to replicate accurately. The fake holograms often lack the depth, color – shifting properties, and other characteristics of genuine holograms, making them a tell – tale sign of a counterfeit ID.

Printing Inks and Toners

The inks and toners used in printing fake ID cards are also important materials. For inkjet – printed fake IDs, standard inkjet inks may be used. However, these inks can fade over time or smear if exposed to moisture. Some counterfeiters may try to use more durable inks, but they still do not match the quality of the specialized inks used in official ID – card printing.

In the case of laser – printed fake IDs, toners are used. Similar to inks, the quality of the toner can vary. Low – quality toners may result in a less sharp print, and the colors may not match those of real ID cards. Additionally, the way the toner adheres to the card material can also be a giveaway, as genuine ID – card printing processes ensure a more even and long – lasting bond between the toner and the card surface.

Common Problems and Solutions

1. Detection of Plastic – Based Fake IDs

Problem: It can be difficult to tell the difference between a real and a fake plastic ID card, especially at first glance.

Solution: Look for signs of poor printing quality. The text and images on fake ID cards may be blurry, pixelated, or have uneven color. Check for security features. Real ID cards have sophisticated security features such as holograms, microprinting, and UV – reactive elements. Use a UV light to check for any hidden or UV – sensitive features that should be present on the real ID but may be lacking or poorly replicated on the fake. Examine the edges of the card. Real ID cards usually have smooth, well – finished edges, while fake ones may have rough or uneven edges where the plastic layers were not properly bonded or cut.

2. Identifying Paper – Based Fake IDs

Problem: Paper – based fake IDs can sometimes be passed off as temporary or low – cost ID options, making detection challenging.

Solution: Test the durability of the card. Paper IDs will tear or crease easily compared to plastic ones. Look at the way the photo and other elements are attached. If they are glued on and look uneven or are starting to peel, it is likely a fake. Check for water resistance. Real ID cards are designed to withstand some exposure to moisture, while paper IDs will quickly get damaged when wet.

3. Spotting Cardboard – Based Fake IDs

Problem: Although cardboard fake IDs are usually of low quality, they may still be presented in situations where a cursory check is made.

Solution: Notice the thickness and texture of the card. Cardboard is much thicker and has a different texture compared to real ID card materials. Check for any signs of amateurish construction, such as hand – written details or poorly attached photos. Real ID cards have professional – looking printed elements and proper photo integration.

4. Verifying Fake Security Threads and Holograms

Problem: Counterfeit security threads and holograms can be difficult to distinguish from the real ones, especially if the fake is of relatively high quality.

Solution: Examine the security thread closely. Real security threads are usually embedded within the card material in a more uniform and precise manner. Fake ones may be glued on or inserted in a haphazard way. For holograms, look for the characteristic optical properties. Real holograms change color and appearance when viewed from different angles, while fake holograms may have a flat or static appearance. Use magnification tools to look for microprinting or other fine details that should be present on real holograms but are often missing on fake ones.

5. Detecting Poor – Quality Printing Inks and Toners

Problem: The inks and toners used in fake ID cards may not be immediately distinguishable from those used in real ones.

Solution: Look for color discrepancies. The colors on fake ID cards may not match the standard colors used in real ID – card printing. Check for fading or smudging. Inks and toners used in fake ID cards are often of lower quality and may fade over time or smudge when rubbed gently. Compare the sharpness of the printed text and images. Real ID – card printing uses high – quality inks and toners that result in sharp, clear prints, while fake ones may have blurry or fuzzy text and images.