In the modern – day landscape, the realm of identity fraud has seen a significant evolution, largely propelled by technological advancements. The issue of fake ID cards has become a matter of growing concern for various sectors, from law – enforcement agencies to businesses that rely on age verification and identity authentication.

Printing Technologies

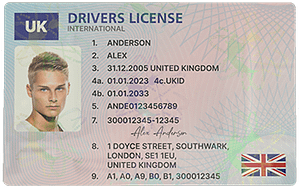

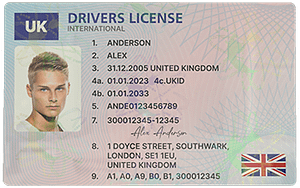

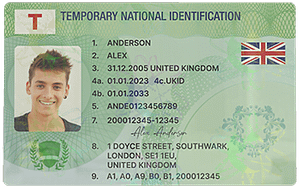

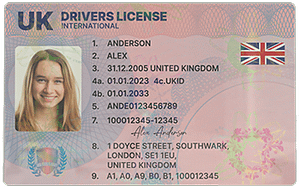

One of the key technological aspects contributing to the increasing believability of fake ID cards is the progress in printing technologies. High – resolution printers, which were once expensive and mainly used in professional printing houses, are now more accessible. These printers can reproduce images and text on ID cards with a level of detail that closely mimics the real thing. For example, they can print high – quality photographs, fine – tuned fonts, and intricate designs that are characteristic of official ID cards. Some counterfeiters are even able to use special inks, such as UV – reactive inks or thermochromic inks, which were previously the exclusive domain of government – issued documents. UV – reactive inks can be made to glow under ultraviolet light, just like the security features on many real ID cards, adding an extra layer of authenticity to the fake.

Digital printing has also made it easier to create custom – made fake ID cards. With software that can manipulate images and text, counterfeiters can modify existing ID card templates to match the details of the person for whom the fake ID is being created. They can change names, dates of birth, and even the appearance of the photograph to make it seem as if the card belongs to a specific individual.

Material and Lamination Technologies

The materials used in fake ID cards have also become more sophisticated. Counterfeiters are now sourcing materials that closely resemble the plastics and papers used in official ID cards. For instance, PVC (polyvinyl chloride), which is commonly used in real ID cards, can be replicated with a high degree of accuracy. The texture, thickness, and flexibility of the fake PVC material can be made to match the real one, making it difficult to detect the forgery just by touch.

Lamination technologies have also played a role. Laminating a fake ID card gives it a more professional and durable look, similar to that of a real ID. Advanced lamination machines can apply a thin layer of plastic over the card, protecting the printed information and adding to the overall authenticity of the card’s appearance. Some counterfeiters even use holographic laminates, which contain complex patterns and designs that are difficult to reproduce without specialized equipment. These holographic laminates can further enhance the convincing nature of the fake ID cards, as they mimic the security features found on many legitimate identification documents.

Data Manipulation and Duplication Technologies

Another area where technology has had a significant impact is in data manipulation and duplication. Scanners and digital cameras have made it easy to copy the information on an existing ID card. Once the data is digitized, it can be easily edited and manipulated using graphic design software. Counterfeiters can change the details on the card, such as the expiration date or the address, while keeping the overall layout and design intact. This makes it difficult for untrained eyes to spot the differences between a real and a fake ID card.

Furthermore, there are technologies available that can duplicate the magnetic stripe or the RFID (radio – frequency identification) chip on an ID card. The magnetic stripe on an ID card contains important information such as the cardholder’s name, date of birth, and identification number. By duplicating this stripe, counterfeiters can create a fake ID card that will pass basic magnetic stripe readers. Similarly, RFID chips are increasingly being used in modern ID cards for quick and contactless identification. Some counterfeiters have managed to replicate these chips, allowing their fake ID cards to function in systems that rely on RFID technology for authentication.

3D Printing and Embossing

3D printing technology has opened up new possibilities for fake ID card production. With 3D printers, counterfeiters can create three – dimensional elements that are present on some ID cards, such as raised text or emblems. Embossing, which is a technique used to create raised text or designs on ID cards, can now be replicated using 3D printing. This makes the fake ID cards look and feel more like the real thing, as the raised elements add a tactile dimension that is characteristic of many official identification documents.

Some 3D printers can also use materials that closely match the color and texture of the original ID card elements. For example, they can create metallic – looking emblems or raised text that has the same sheen and feel as the real ones. This level of detail in replication makes it extremely challenging to distinguish between a genuine and a fake ID card just by visual and tactile inspection.

Common Problems and Solutions

- Problem: Difficulty in Detecting Print Quality Differences

Solution: Law – enforcement agencies and businesses should invest in high – quality magnifying devices and comparison tools. These can be used to closely examine the print quality of ID cards. Trained personnel should be able to identify subtle differences in font sharpness, ink saturation, and image resolution between real and fake ID cards. Additionally, developing databases of known real ID card print characteristics can help in quick verification. - Problem: Inability to Differentiate Material Types

Solution: Implementing material analysis tools, such as spectrometers, can be helpful. These devices can analyze the chemical composition of the ID card material and compare it with the known composition of real ID card materials. Staff should also be trained to recognize the typical feel and texture of genuine ID card materials, and any deviation should be a red flag for further investigation. - Problem: Failure to Identify Manipulated Data

Solution: Employing digital verification systems that can cross – reference the data on the ID card with official databases. These systems can quickly detect if the information on the ID card has been manipulated. For example, if the date of birth on the ID card does not match the age calculation based on the current date, it could be a sign of a fake. Additionally, using advanced optical character recognition (OCR) technology to extract and analyze the text on the ID card can help in identifying any irregularities in the data. - Problem: Overlooking Holographic and Security Feature Duplications

Solution: Providing employees with specialized UV – light scanners and other security feature detection devices. These can be used to check for the presence and authenticity of holographic laminates, UV – reactive inks, and other security features. Training programs should also be in place to educate employees on the specific security features of different types of ID cards and how to identify fake versions of these features. - Problem: Inadequate Detection of 3D – Printed and Embossed Elements

Solution: Using tactile inspection techniques in addition to visual inspection. Trained individuals should be able to feel for the consistency and quality of the raised elements on the ID card. For example, real embossed text or emblems usually have a smooth and well – defined edge, while fake ones may have a rough or uneven surface. Additionally, using high – resolution imaging devices to closely examine the 3D – printed elements can help in detecting any signs of forgery.